Open Channel Spillways

Contents

- Earth and Rock Spillways

- Design, Maintenance, and Safety for Earth and Rock Spillways

- Concrete Chutes and Weirs

- Design, Maintenance, and Safety for Concrete Chutes and Weirs

- Dam Owner Academy Series

- Save this page as printable Dam Owner's Fact Sheets [PDF]

Earth and Rock Spillways

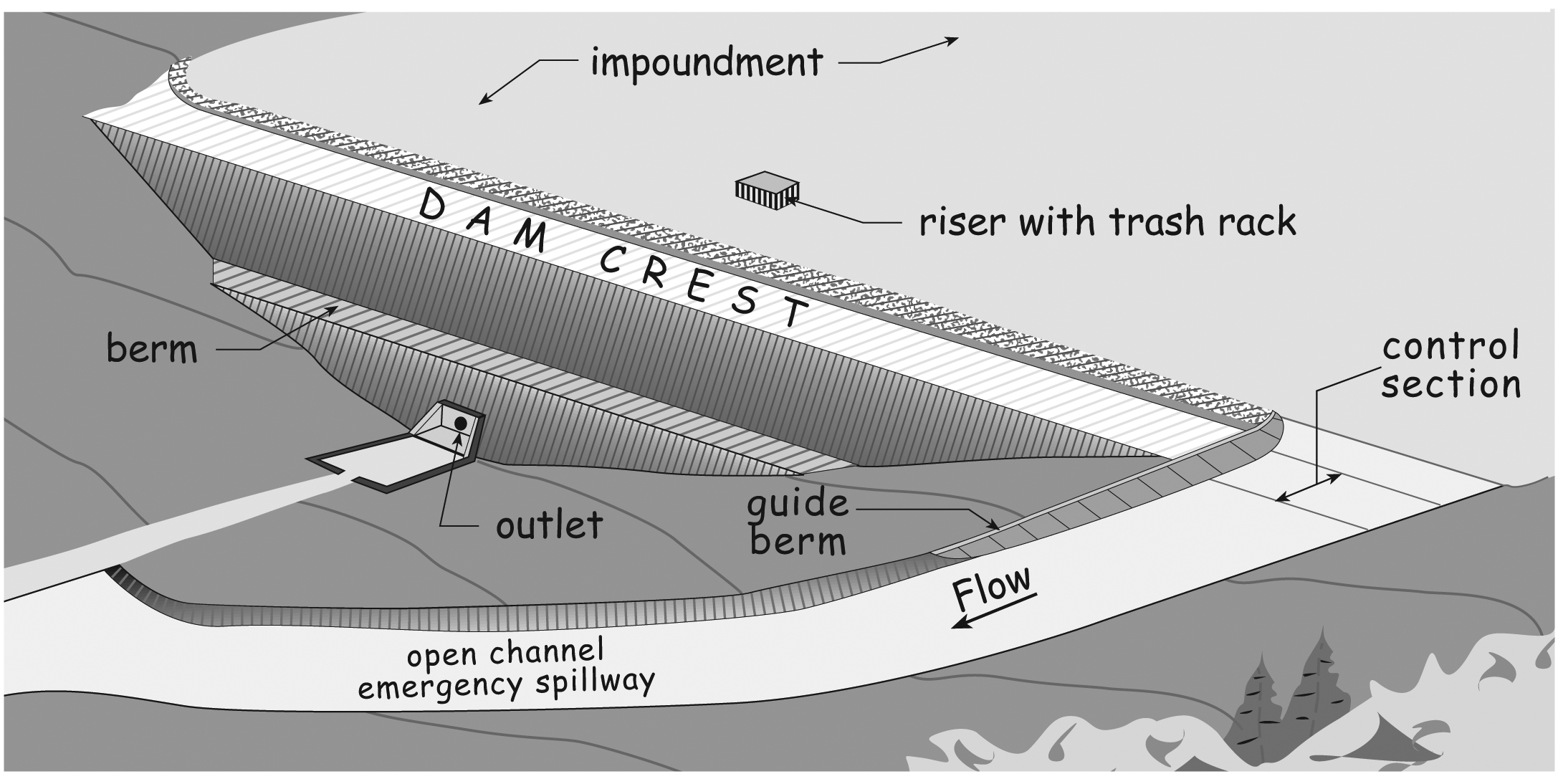

Open channels are often used as the emergency spillway and sometimes as the principal spillway for dams. A principal spillway is used to pass normal inflows, and an emergency spillway is designed to operate only during large flood events, usually after the capacity of the principal spillway has been exceeded.

For dams with pipe conduit principal spillways, an open channel emergency spillway is almost always required as a backup in case the pipe becomes clogged. Open channels are usually located in natural ground adjacent to the dam and can be vegetated, rocklined, or cut in rock.

Design

Flow through an emergency spillway does not necessarily indicate a problem with the dam, but high velocity flows can cause severe erosion and result in a permanently lowered lake level if not repaired. Proper design of an open channel spillway will include provisions for minimizing any potential erosion. One way to minimize erosion is to design a flatter channel slope to reduce the velocity of the flow. Earthen channels can be protected by a good grass cover, an appropriately designed rock cover, concrete or various types of erosion control matting. Rock-lined channels must have adequately sized riprap to resist displacement and contain an appropriate geotextile fabric or granular filter beneath the rock. Guide berms are often required to divert flow through open channels away from the dam to prevent erosion of the embankment fill. If an open channel is used for a principal spillway, it must be rock-lined or cut in rock due to more frequent or constant flows.

Many States have requirements, based on hazard classification, for how often an earth (grass-lined) or a rock-lined emergency spillway should be used prior to maintenance procedures. It is important to check the guidelines or regulations in your State.

Maintenance

Maintenance should include, but not be limited to, the following items:

Grass-covered channels should be mowed at least twice per year to maintain a good grass cover and to prevent trees, brush and weeds from becoming established. Poor vegetal cover can result in extensive and rapid erosion when the spillway flows. Repairs can be costly. Reseeding and fertilization may be necessary to maintain a vigorous growth of grass.

One suggested seed mixture is 30% Kentucky Bluegrass, 60% Kentucky 31 Fescue, and 10% Perennial Ryegrass.

Trees and brush must be removed from the channel. Tree and brush growth reduces the discharge capacity of the spillway channel. This increases the lake level during large storm events which can lead to overtopping and failure of the dam.

Erosion in the channel must be repaired quickly after it occurs. Erosion can be expected in the spillway channel during high flows, and can also occur because of rainfall and runoff, especially in areas of poor grass cover. Terraces or drainage channels may be necessary in large spillway channels where large amounts of rainfall and runoff may concentrate and have high velocities. Erosion of the side slopes may deposit material in the spillway channel, especially where the side slopes meet the channel bottom. In small spillways, this can significantly reduce the discharge capacity. This condition often occurs immediately after construction before vegetation becomes established. In these cases, it may be necessary to reshape the channel to provide the necessary capacity.

All obstructions should be kept out of the channel. Open channel spillways often are used for purposes other than passage of flood flows. Among these uses are reservoir access, parking lots, boat ramps, boat storage, pasture and cropland. Permanent structures (buildings, fences, etc.) should not be constructed in these spillways. If fences, bridges or other such structures are absolutely necessary, they should cross the spillway far enough upstream or downstream from the control section so that they do not interfere with the flow Construction of any structures in or across the channel may require prior approval from the State.

Weathering of rock channels can be a serious problem and is primarily due to freeze/thaw action. Deterioration because of sun, wind, rain, chemical action and tree root growth also occurs. Weathered rock is susceptible to erosion and displacement during high flows; therefore, rock channels are often designed with 1 to 3 feet of earth with a grass cover over the rock surface to help insulate the rock from the effects of freeze/thaw action.

Monitoring

Open channel spillways should be monitored for erosion, poor vegetal cover, growth of trees and brush, obstructions, and weathering and displacement of rock. Monitoring should take place on a regular basis and after large flood events. It is important to keep written records of observations. Photographs provide invaluable records of changing conditions. All records should be kept in the operation, maintenance, and inspection manual for the dam.

Concrete Chutes and Weirs

Concrete chutes and weirs are used for principal spillways and emergency spillways. The principal spillway is used to pass normal flows, and the emergency spillway provides additional flow capacity during large flood events. If the principal spillway for a dam is a concrete weir and/or chute, the flow capacity may be large enough that an emergency spillway is not needed. Unlike grass-lined channel spillways that should always be located on natural ground, a concrete weir or chute may be located on the dam, but must be properly designed so that the integrity of the dam is not endangered.

The main components of a concrete chute spillway are the inlet structure, control section, discharge channel, and outlet erosion control structure. The inlet structure conveys water to the control section. The control section is the highest point in the channel and regulates the outflow from the reservoir. It is usually located on or near the crest of the dam. The control section may consist of a concrete weir or may simply be the most elevated slab in the floor of the chute. The discharge channel is located downstream of the control section and conveys flow to the outlet erosion control structure. This structure is designed to dissipate most of the erosive energy of the flow before it enters the downstream channel.

Design, Maintenance, and Safety for Concrete Chutes and Weirs

Alignment: For good hydraulic performance, abrupt changes should be avoided. This applies to sudden changes in vertical elevation of the chute floor, abrupt widening or narrowing of the chute, and sharp turns in the chute. Anything that will abruptly disrupt or change the direction of the flow in the chute will reduce flow capacity and will place more stress on the concrete. The best performance is obtained when the distribution of flow is even across the channel.

Settlement and Movement: Abnormal settlement, heaving, deflections, and lateral movement of the sidewalls or floor slabs of the spillway can occur. Movements are usually caused by a loss of underlying material, excessive settlement of the fill, or the buildup of water pressure behind or under the structure. Any abnormal settlement, heaving, deflections or lateral movement in the concrete spillway should be immediately investigated by a registered professional engineer knowledgeable about dam safety. As necessary, plans and specifications for repair to the spillway should also be promptly developed and implemented by a registered professional engineer.

The concrete sidewalls and floor of the chute must have enough strength to withstand water loads, soil/fill loads, uplift forces, weathering, and abrasion. The forces of weathering, movement of abrasive materials by water flowing in the spillway, or cavitation may cause surface defects or more serious concrete deterioration.

The freeze-thaw cycle is the most damaging weathering force acting on exposed concrete. The concrete’s durability and resistance to weathering and deterioration will be determined by the concrete mix, age of the concrete, and proper sealing of the joints. Typical problems with concrete structures include scaling, spalling, honeycombing, bugholes, and popouts. Please refer to the “Problems with Concrete Materials” fact sheet for further explanation of these problems and more details about concrete durability and design. Plans and specifications for repair of structural cracks, or other structural problems, should be developed and implemented by a registered professional engineer so that the integrity of the spillway and/or embankment is not jeopardized.

Undermining: Undermining of the chute may occur at any point along its length. The chute may become undermined at the inlet and/or outlet due to an inadequate cutoff wall or erosion protection. Erosion beneath and alongside the spillway may also be caused by seepage and inadequate drainage. Undermining and erosion will lead to settlement of the undermined portions of the chute. If the concrete spillway is located on the embankment, undermining and collapse of portions of the chute will jeopardize the safety of the dam. If the spillway is located in the abutment, erosion and lowering of the lake level may result. A registered professional engineer should be hired to develop plans and specifications to repair undermining of the chute.

Cutoff Wall and Endwall: A cutoff wall should be placed at the entrance to the concrete chute to prevent the flow approaching and entering the chute from flowing beneath and undermining the floor slabs. Undermining of the chute can cause cracking and collapse of the slabs as the underlying material is eroded away. In addition, a cutoff wall is necessary at the downstream end of the chute to prevent undermining by flows exiting the chute and entering the downstream channel. The cutoff wall or endwall should be founded on bedrock or have adequate support to provide stability and prevent undermining of the wall itself.

Outlet Erosion Control Structure: The discharge at the outlet may exit the chute at a high velocity. Based on the anticipated velocity, energy, and volume of flow, a structure may be needed to protect the spillway and/or dam from erosion and undermining. Please refer to the “Outlet Erosion Control Structures” fact sheet for more detailed information.

Seepage: The rate and content of flow from weep holes and relief drains must be monitored and documented regularly. Muddy flow may indicate erosion of fill material along the spillway or piping through the embankment. The presence of soil particles or muddy flow from the drains indicates that the filter or underdrainage is not functioning properly and is allowing the migration of soil particles from the embankment. Sudden increases in flow, or muddy flow from the drains should be immediately investigated by a registered professional engineer to determine the cause and severity of the problem. Plans and specifications to properly control the seepage and repair the drain(s) and embankment should also be developed and carried out under the direction of a registered professional engineer.

In addition to monitoring the amount of flow, normal maintenance consists of removing all obstructions from drain holes and pipes to allow free drainage. Typical obstructions include debris, gravel, sediment and rodent nests. Water should not be permitted to submerge the pipe outlets for extended periods of time. This will inhibit inspection and maintenance and may cause the drains to clog. Also see the “Seepage Through Earthen Dams” fact sheet for more information.

Underdrainage and Weep Holes: Weep holes, relief drains and underdrains must be included with the concrete chute to relieve excessive water pressure or infiltration from behind the walls and floor. The drainage system for the chute should consist of correctly placed and sized drainage holes, perforated pipes, and filter and bedding materials, such as sand and gravel. Seepage can occur through the dam, along the contact between the embankment and the concrete chute, or through open joints and cracks. Uncontrolled seepage flow along the structure can erode the underlying fill material (undermining) which may cause cracking or buckling of the slabs. Excessive pressure behind the walls and floor of the chute can cause cracking and heaving of the concrete. The freeze-thaw cycle can increase the amount of stress and strain on the concrete and can also cause heaving, cracking and additional serious damage to the structure. Weep holes, relief drains, and underdrainage for a concrete chute spillway should be designed by a registered professional engineer.

Dam Owner Academy: Spillways & Outlet Works

The Dam Owner Academy is a series of videos to educate and inform owners on all aspects of operating and maintaining a dam safely. The videos concisely present the critical basics of owner responsibilities and are available as a free resource for owners and those conducting owner outreach programs.

Open channel spillways are discussed in the "Spillways & Outlet Works" video.