Problems with Metal Materials

Contents

- Corrosion

- Prevention Techniques

- Maintenance, Inspection, and Safety Considerations

- Save this page as a printable Dam Owner's Fact Sheet [PDF]

Corrosion

Corrosion is a common problem for spillway conduits and other metal appurtenances. Corrosion is the deterioration or breakdown of metal because of a reaction with its environment. Exposure to moisture, acidic conditions, or salt will accelerate the corrosion process. Acid runoff from strip-mined areas will cause rapid corrosion of metal conduits. In these areas, conduits made of less corrodible materials such as concrete or plastic should be used. Soil types also factor into the amount of corrosion. Clayey soils can be more corrosive than sandy soils since they are poorly drained and poorly aerated. Silts are somewhere in between clays and sands. Some examples of metal conduits include ductile iron, smooth steel, and corrugated metal.

Corrosion is a common problem for spillway conduits and other metal appurtenances. Corrosion is the deterioration or breakdown of metal because of a reaction with its environment. Exposure to moisture, acidic conditions, or salt will accelerate the corrosion process. Acid runoff from strip-mined areas will cause rapid corrosion of metal conduits. In these areas, conduits made of less corrodible materials such as concrete or plastic should be used. Soil types also factor into the amount of corrosion. Clayey soils can be more corrosive than sandy soils since they are poorly drained and poorly aerated. Silts are somewhere in between clays and sands. Some examples of metal conduits include ductile iron, smooth steel, and corrugated metal.

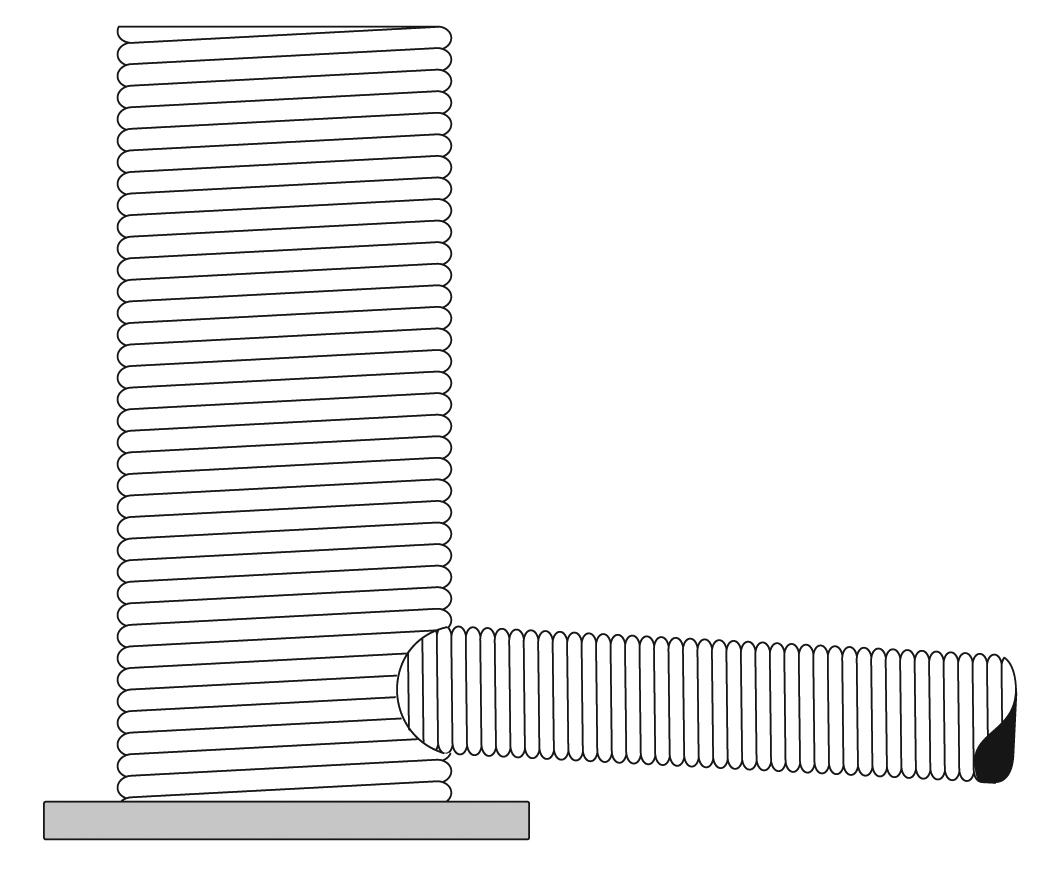

Corrugated metal pipe is not recommended for use in dams since the service life for corrugated metal is only 25 to 30 years, whereas the life expectancy for dams is much longer.

In areas of acidic water, the service life can be much less. Therefore, corrugated metal spillway conduits, such as the pipe and riser spillway illustrated here, typically need to be repaired or replaced early in the dam’s design life, which can be very expensive.

Prevention Techniques

Conduit coating is an effective way of controlling corrosion of metal conduits if used properly. It is relatively inexpensive and extends the life of the conduit. Some examples of coatings include cement-mortar, epoxy, aluminum, or polyethylene film. Asphalt (bituminous) coatings are not recommended since their service life is usually only one or two years. Coatings must be applied to the conduit prior to installation and protected to ensure that the coating is not scratched off. Coatings applied to conduits in service are generally not very effective because of the difficulty in establishing an adequate bond.

Corrosion can also be controlled or arrested by installing cathodic protection. A metallic anode such as magnesium (or zinc) is buried in the soil and is connected to the metal conduit by wire. Natural voltage current flowing from the magnesium (anode) to the conduit (cathode) will cause the magnesium to corrode and not the conduit. However, sufficient maintenance funds should be allocated for the regular inspection of this active system.

If corrosion is allowed to continue, metal conduits will rust out. The spillway must be repaired before water flows through the rusted-out portion of the conduit and erodes the fill material of the embankment. Continued erosion can lead to failure of the dam. Sliplining can be an economical and effective method of permanently restoring deteriorated spillways. During sliplining, a smaller diameter pipe is inserted into the old spillway conduit and then grout is used to fill in the void between the two pipes. If sliplining the spillway is not feasible, the lake may need to be drained and a new spillway must be installed. A registered professional engineer should be retained to develop and submit plans and specifications for any major modifications such as spillway sliplining or replacement.

Maintenance, Inspection, and Safety Considerations

Corrosion of the metal parts of the operating mechanisms such as lake drain valves and sluice gates can be effectively treated by keeping these parts lubricated and /or painted. If the device has not been operated in several years, a qualified person (i.e. manufacturer’s representative or registered professional engineer) should inspect it to determine its operability. Caution must be used to prevent the mechanism from breaking. A registered professional engineer may be needed to prepare plans and specifications for repair if the device is determined to be inoperable.

Regular inspection and monitoring is essential to detect any problems with metal materials. Coatings on metal pipes should be inspected for scratched and worn areas. The inspector should also look for corrosion inside the spillway conduit. Proper ventilation and confined space precautions must be considered when entering the spillway conduit system. If using cathodic protection, regular inspections are required to verify that the system is working properly. It is important to keep written records of the amount of surface rust, pitting, and corrosion on any metal surface. Areas of thin metal should be monitored more frequently and repaired or replaced if they rust out. Photographs provide invaluable records of changing conditions. A rapidly changing condition may indicate a very serious problem, and the State Dam Safety Agency should be contacted immediately. All records should be kept in the operation, maintenance, and inspection manual for the dam.