Problems with Plastic (Polymer) Materials

Contents

Plastics are often used as spillway and lake drain pipes in dam construction and repair. The most common plastic pipes are high-density polyethylene (HDPE) and polyvinyl chloride (PVC). The advantages of using plastic pipe include excellent abrasion resistance, chemical corrosion resistance, low maintenance, and long-life expectancy. Naturally occurring chemicals in soils will not degrade plastic pipe and cause it to rot or corrode. Plastic pipes are also much easier to handle and install compared to heavier concrete and steel pipes.

Backfill

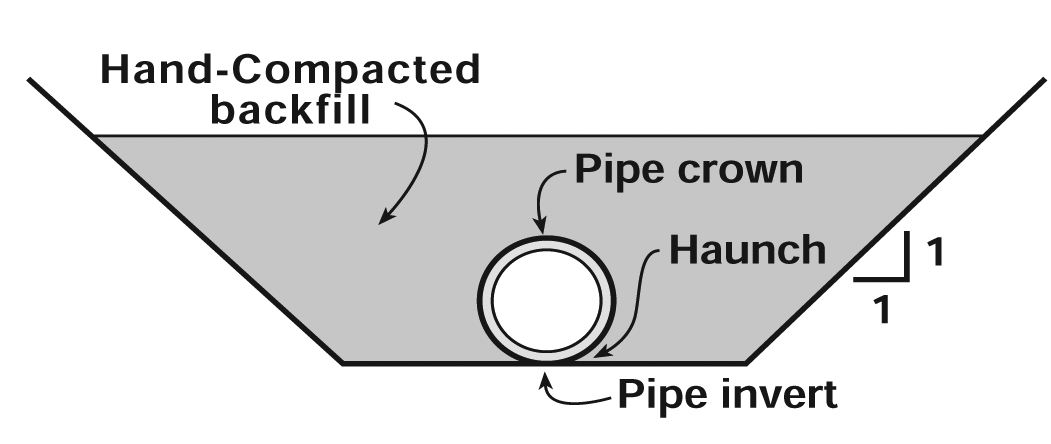

Plastic pipes are considered flexible, and they get their strength from the material and the surrounding backfill whereas rigid pipes, such as concrete, get their strength from the material and the pipe structure. Backfill around plastic pipes must be properly compacted and in full contact with the pipe. It is important to take special care in the haunch area to prevent the pipe from lifting off the subgrade and disrupting vertical alignment.

Plastic pipes are considered flexible, and they get their strength from the material and the surrounding backfill whereas rigid pipes, such as concrete, get their strength from the material and the pipe structure. Backfill around plastic pipes must be properly compacted and in full contact with the pipe. It is important to take special care in the haunch area to prevent the pipe from lifting off the subgrade and disrupting vertical alignment.

Symmetric backfilling is also required to prevent the pipe from being out of lateral alignment.

When designing a new spillway system, a registered professional engineer will be required to specify the correct type of pressurized plastic pipe that can be used. The pipe must be able to withstand the pressures from the weight of the embankment without crushing or buckling. The joints must also be watertight. Not all plastic pipe will meet these requirements.

Degradation

As with other plastic materials, ultraviolet light degradation can be a problem. Photo-degradation can cause plastic to become brittle and crack. Carbon black is the most effective additive to enhance the photo-degradation resistance of plastic materials. Pipes containing carbon black can be safely stored outside in most climates for many years without damage from ultraviolet exposure.

Plastic pipes can be affected by liquid hydrocarbons such as gasoline and oil. If hydrocarbons come in contact with plastic pipe, they will permeate the pipe wall causing swelling and loss of strength. However, if the hydrocarbons are removed, the effects are reversible.

Inspection

Regular inspection and monitoring is essential to detect any problems with plastic materials. Plastic pipes should be inspected for deformation and cracking. The inspector should also look at the interior condition of the spillway pipe. Proper ventilation and confined space precautions must be considered when entering the spillway pipe system. It is important to keep written records of pipe dimensions to note deformation and the length and width of cracks. Photographs provide invaluable records of changing conditions. A rapidly changing condition may indicate a very serious problem, and the State Dam Safety Agency should be contacted immediately. All records should be kept in the operation, maintenance, and inspection manual for the dam.