Design and Maintenance of Trashracks

Contents

- Common Problems

- Trashrack Design

- Fish Protection

- Anti-Vortex Devices

- Maintenance

- Dam Owner Academy Series

- Save this page as a printable Dam Owner's Fact Sheet [PDF]

The principal spillway for dams can be one of several designs. The proper operation of these spillways is an important part of maintaining the overall safety of the dam. Pipe and riser, drop inlet, and slant pipe spillways are susceptible to obstruction and damage by floating debris such as leaves, branches, and logs. One device used to ensure that these spillways operate correctly is a trashrack. Trashracks are designed to keep trash and other debris from entering the spillway and causing damage.

The benefits of a properly designed and maintained trashrack include the following:

- Efficient use of the existing spillway system that will maintain the design discharge/storage capacity of the dam and prevent overtopping.

- Prevention of costly maintenance items such as the removal of debris from the spillway, repair or replacement of damaged spillway components, and the repair of erosion in emergency spillway.

- A reduction in the amount of fish lost through the spillway system if a fish screen is used.

Common Problems

Trashracks usually become plugged because the openings are too small or the head loss at the inlet causes material and sediment to settle out and accumulate. Small openings will cause debris such as twigs and leaves to accumulate on the trashrack bars. This buildup will cause progressively larger debris to accumulate against the trashrack bars. Ultimately, this will result in the complete blockage of the spillway inlet.

Pipe and riser spillways can also become blocked by a buildup of debris in the spillway. This type of blockage occurs when no trashrack is in place, or if the openings are too large.

In many spillway systems, the size of the outlet conduit is smaller than the size of the inlet. Therefore, it is incorrect to assume that debris which passes through the inlet will not obstruct the flow through the outlet. Large debris, such as logs and tree limbs, can become lodged in the transitions in the spillway. This reduces the capacity of the spillway and could cause damage. An obstructed outlet pipe can be a major problem because removal of large debris from inside the spillway can be very difficult.

A partially blocked spillway reduces the capacity of the spillway and may also create a higher than normal pool level. The combination of these two factors can dramatically reduce the discharge & storage capacity of the dam. A reduction in the discharge & storage capacity of a dam increases the likelihood that the dam will be overtopped during a severe storm event. Overtopping, for even a short period of time, can cause damage to the embankment and possibly failure of the dam. If the dam has an emergency spillway, a blocked principal spillway will cause more frequent flows in the emergency spillway. Since emergency spillways are usually grass lined channels designed for infrequent flows of short duration, serious damage is likely to result.

Trashrack Design

A well-designed trashrack will stop large debris that could plug the conduit, but allow unrestricted passage of water and smaller debris. The larger the outlet conduit, the larger the trashrack opening should be. In the design of a trashrack, the openings should be sized so that they measure one-half the nominal dimension of the outlet conduit.

For example, if the outlet pipe is 18 inches in diameter, the trashrack openings should be the effective equivalent of 9 inches by 9 inches; if the outlet conduit is 3 feet by 5 feet, the trashrack openings should be the effective equivalent of 18 inches by 18 inches. This rule applies up to a maximum trashrack opening of two feet by two feet. For an outlet conduit with a nominal dimension of 12 inches or less, the trashrack openings should be at least 6 inches by 6 inches. This prevents large debris from passing through the inlet and blocking the outlet conduit while allowing smaller debris (leave, sticks, etc.) to flush through the spillway system. The trashrack should be securely fastened to the inlet. The connection must be strong enough to withstand the hydrostatic and dynamic forces exerted on the trashrack during periods of high flow.

Fish Protection

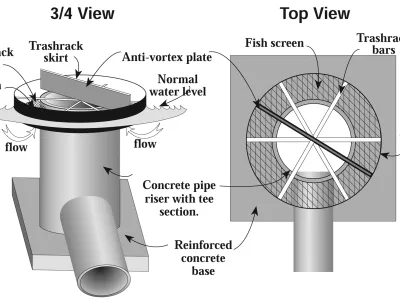

Many owners are concerned about losing fish through trashracks that have large openings. If this is a concern, a metal plate surrounding the riser or drop inlet which extends above and below the normal pool level should be installed. On the bottom of the plate, a metal screen should be attached and connected to the riser pipe. The solid plate at the water level will prevent the fish and floating debris from passing over the crest of the riser. The underwater screen will keep the fish from moving under the metal plate and through the spillway. The underwater screen will not become blocked because most of the debris floats on the water surface. If this design is used, the area between the inside of the cylinder and the outside of the riser must be equal to or greater than the area inside the riser.

Anti-Vortex Devices

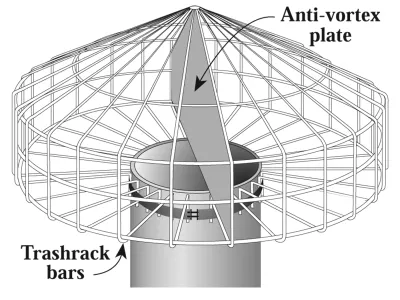

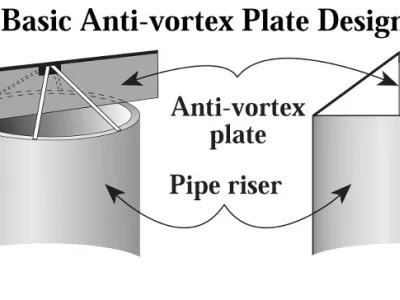

An anti-vortex device can easily be incorporated into most trashrack designs. A common anti-vortex device is a flat metal plate which is placed on edge and attached to the inlet of the spillway. See Figure above. The capacity of the spillway will be increased by equipping the trashrack with an anti-vortex plate. The anti-vortex plate increases capacity by preventing the formation of a flow inhibiting vortex during periods of high flow.

Maintenance

Maintenance should include periodic checks of the trashrack for rusted and broken sections and repairing as needed. Trashracks should be checked frequently during and after storm events to ensure they are functioning properly and to remove accumulated debris. Extreme caution should be used when attempting to remove accumulated debris during periods of high flow.

Dam Owner Academy: Spillways & Outlet Works

The Dam Owner Academy is a series of videos to educate and inform owners on all aspects of operating and maintaining a dam safely. The videos concisely present the critical basics of owner responsibilities and are available as a free resource for owners and those conducting owner outreach programs.

Trashracks are discussed in the "Spillways & Outlet Works" video.