Upstream Slope Protection

Contents

- Rock Riprap

- Soil Cement

- Inspection and Monitoring

- Dam Owner Academy Series

- Save this page as a printable Dam Owner's Fact Sheet [PDF]

Slope protection is usually needed to protect the upstream slope against erosion due to wave action. Without proper slope protection, a serious erosion problem known as “beaching” can develop on the upstream slope.

The repeated action of waves upon a vegetated embankment surface over time may erode embankment material and deposit it farther down the slope, creating a “beach.” The amount of erosion depends on the predominant wind direction, the orientation of the dam, the steepness of the slope, water level fluctuations, boating activities, and other factors. Further erosion can lead to cracking and sloughing of the slope which can extend into the crest, reducing its width. When erosion occurs and beaching develops on the upstream slope of a dam, repairs should be made as soon as possible. However, an erosion scarp less than 1 foot high may be stable and not require repair.

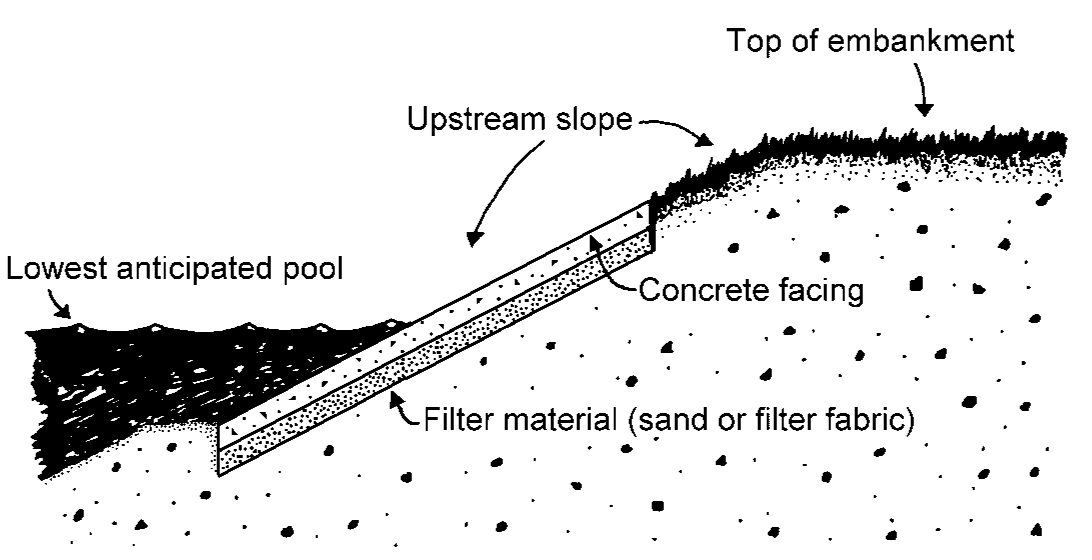

The upstream face of a dam is commonly protected against wave erosion by placement of a layer of rock riprap over a layer of bedding and a filter material. Other material such as concrete facing, soil-cement, fabri-form bags, slush grouted rocks, steel sheet piling, and articulated concrete blocks can also be used. Vegetative protection combined with a berm on the upstream slope can also be effective.

Rock Riprap

Rock riprap consists of a heterogeneous mixture of irregular shaped rocks placed over gravel bedding and a sand filter or geotextile fabric. The smaller rocks help to fill the spaces between the larger pieces forming an interlocking mass. The filter prevents soil particles on the embankment surface from being washed out through the spaces (or voids) between the rocks. The maximum rock size and weight must be large enough to break up the energy of the maximum anticipated wave action and hold the smaller stones in place. If the rock size is too small, it will eventually be displaced and washed away by wave action. If the riprap is sparse or if the filter or bedding material is too small, the filter material will wash out easily, allowing the embankment material to erode. Once erosion has started, beaching will develop if remedial measures are not taken.

The dam owner should expect some deterioration (weathering) of riprap. Freezing and thawing, wetting and drying, abrasive wave action, and other natural processes will eventually break down riprap. Its useful life varies with the characteristics of the stone used. Stone for riprap should be rock that is dense, well cemented, abrasion resistant, and angular in shape to resist deterioration and create an interlocking barrier. Vegetative growth within the slope protection is undesirable because it can displace stone and disturb the filter material. Heavy undergrowth prevents an adequate inspection of the upstream slope and may hide potential problems. For additional information, see the “Trees and Brush” fact sheet.

Sufficient maintenance funds should be allocated for the addition of riprap and the removal of vegetation. Severe erosion or reoccurring problems may require a registered professional engineer to design a more effective slope protection.

Soil Cement

Soil-Cement consists of a well compacted mixture of soil, Portland cement, and water compacted to a high density. The relative proportions of soil, cement and water in the soil-cement mixture are based on the results of laboratory tests on specially prepared specimens to determine its durability and strength properties over a range soil gradations and cement contents. A soil-cement mixture of adequate durability and strength can be designed, and slope protection constructed, using almost any type of soil. Soil-cement can be placed by either the "plating" or "stair-step" method. The plating method of placement consists of one or more lifts of soil-cement placed parallel to the slope. The plating method can be considered for use on small dams where wave action is not severe. Even for small dams this method is not considered for areas where significant wave action is expected.

The stair-step method of construction consists of placing the soil-cement in horizontal lifts of 6 to 9 inches. An approximate 9-inch spread thickness results in a 6-inch compacted thickness. The width of each lift is generally 8 to 10 feet to accommodate placing and compaction equipment. See Figure. Use of pneumatic-tired rollers or steel drum rollers is the most common used compact soil-cement in the stair-stop method.

RCC (roller compacted concrete) has also been used as slope protection and is designed and installed similar to soil cement. Consideration should be given that other methods maybe more appropriate in freeze-thaw regions of the country.

Bureau of Reclamation Design Standard No. 13, Embankment Dams, Chapter 17: Soil Cement Slope Protection and the Portland Cement Association Soil -Cement Construction Handbook are good references for design engineers.

As with any type of slope protection, problems will develop if the concrete facing has not been properly designed or installed. Concrete facing often fails because wave action washes soil particles from beneath the slabs through joints and cracks. This process is known as undermining, which will continue until large voids are created. Detection of voids is difficult because the voids are hidden. Failure of the concrete facing may be sudden and extensive. Concrete facing should be monitored for cracks and open joints. Open joints should be sealed with plastic fillers and cracks should be grouted and sealed. For additional information, see the “Problems with Concrete Materials” fact sheet.

As with any type of slope protection, problems will develop if the concrete facing has not been properly designed or installed. Concrete facing often fails because wave action washes soil particles from beneath the slabs through joints and cracks. This process is known as undermining, which will continue until large voids are created. Detection of voids is difficult because the voids are hidden. Failure of the concrete facing may be sudden and extensive. Concrete facing should be monitored for cracks and open joints. Open joints should be sealed with plastic fillers and cracks should be grouted and sealed. For additional information, see the “Problems with Concrete Materials” fact sheet.

Inspection and Monitoring

Regular inspection and monitoring of upstream slope protection is essential to detect any problems. It is important to keep written records of the location and extent of any erosion, undermining, or deterioration of the riprap, wave berm or other slope protection. Photographs provide invaluable records of changing conditions. A rapidly changing condition may indicate a very serious problem, and appropriate dam safety officials should be contacted. All records should be kept in the operation, maintenance, and inspection manual for the dam.

Dam Owner Academy: Operation & Maintenance Plans

The Dam Owner Academy is a series of videos to educate and inform owners on all aspects of operating and maintaining a dam safely. The videos concisely present the critical basics of owner responsibilities and are available as a free resource for owners and those conducting owner outreach programs.

Upstream Slope Protection is discussed in the 'Operation & Maintenance Plans' video.