Outlet Erosion Control Structures (Stilling Basins)

Contents

- Headwalls and Endwalls

- Impact Basins

- Type II and Type III Basins

- Baffled Chutes

- Plunge Pools

- Dam Owner Academy Series

- Save this page as a printable Dam Owner's Fact Sheet [PDF]

Water moving through the spillway of a dam contains a large amount of energy. This energy can cause erosion at the outlet which can lead to instability of the spillway. Failure to properly design, install, or maintain a stilling basin could lead to problems such as undermining of the spillway and erosion of the outlet channel and/or embankment material. These problems can lead to failure of the spillway and ultimately the dam. A stilling basin provides a means to absorb or dissipate the energy from the spillway discharge and protects the spillway area from erosion and undermining. An outlet erosion control structure such as a headwall/endwall, impact basin, United States Department of the Interior, Bureau of Reclamation Type II or Type III basin, baffled chute, or plunge pool is considered an energy dissipating device. The performance of these structures can be affected by the tailwater elevation. The tailwater elevation is the elevation of the water that is flowing through the natural stream channel downstream during various flow conditions.

A headwall/endwall, impact basin, Type II or Type III basin, and baffled chute are all constructed of concrete. Concrete structures can develop surface defects such as minor cracking, bugholes, honeycombing, and spalling. Concrete structures can have severe structural defects such as exposed rebar, settlement, misalignment and large cracks. Severe defects can indicate structural instability.

Headwalls and Endwalls

A headwall/endwall located at or close to the end of the discharge conduit will provide support and reduce the potential for undermining. A headwall/endwall is typically constructed of concrete, and it should be founded on bedrock or have an adequate foundation footing to provide support for stability. A headwall/endwall can become displaced if it is not adequately designed and is subject to undermining. Displacement of the headwall/endwall can lead to separation of the spillway conduit at the joints which could affect the integrity of the spillway conduit. If a concrete structure develops the structural defects mentioned in the opening paragraphs, or if the discharge spillway conduit does not have a headwall/endwall, then a registered professional engineer should be contacted to evaluate the stability of the outlet.

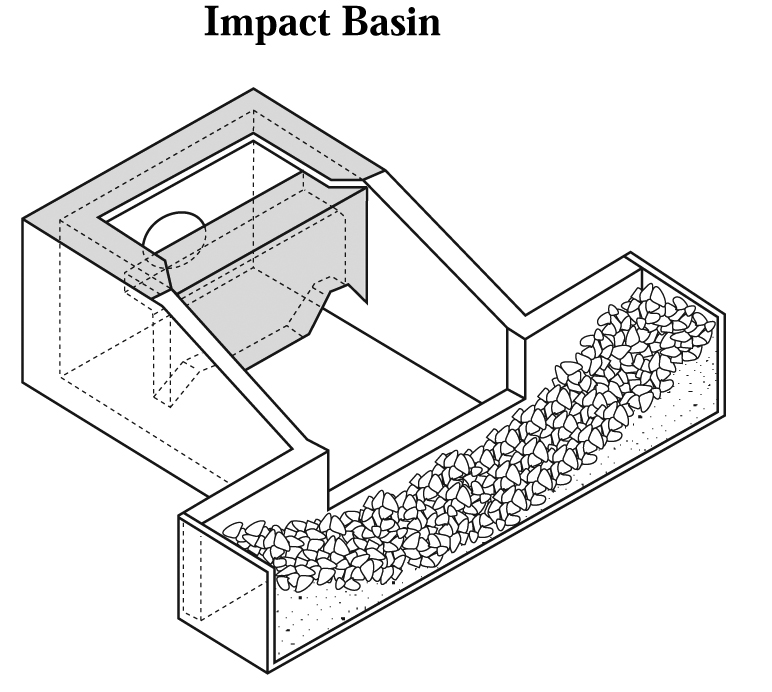

Impact Basins

A  concrete impact basin is an energy dissipating device located at the outlet of the spillway in which flow from the discharge conduit strikes a vertical hanging baffle. Discharge is directed upstream in vertical eddies by the horizontal portion of the baffle and by the floor before flowing over the endsill. Energy dissipation occurs as the discharge strikes the baffle, thus, performance is not dependent on tailwater. Most impact basins were designed by the United States Department of Agriculture, Natural Resources Conservation Service and the United States Department of Interior, Bureau of Reclamation. If any of the severe defects that are referenced in the opening paragraphs are observed, a registered professional engineer should be contacted to evaluate the stability of the outlet.

concrete impact basin is an energy dissipating device located at the outlet of the spillway in which flow from the discharge conduit strikes a vertical hanging baffle. Discharge is directed upstream in vertical eddies by the horizontal portion of the baffle and by the floor before flowing over the endsill. Energy dissipation occurs as the discharge strikes the baffle, thus, performance is not dependent on tailwater. Most impact basins were designed by the United States Department of Agriculture, Natural Resources Conservation Service and the United States Department of Interior, Bureau of Reclamation. If any of the severe defects that are referenced in the opening paragraphs are observed, a registered professional engineer should be contacted to evaluate the stability of the outlet.

U.S. Department of Interior & Bureau of Reclamation Type II and Type III Basins

Type II and Type III basins reduce the energy of the flow discharging from the outlet of a spillway and allow the water to exit into the outlet channel at a reduced velocity. Type II energy dissipators contain chute blocks at the upstream end of the basin and a dentated (tooth-like) endsill. Baffle piers are not used in a Type II basin because of the high velocity water entering the basin.

Type III energy dissipators can be used if the entrance velocity of the water is not high. They contain baffle piers which are located on the stilling basin apron downstream of the chute locks. Located at the end of both the Type II and Type III basins is an endsill. The endsill may be level or sloped, and its purpose is to create the tailwater which reduces the outflow velocity. If any of the severe defects associated with concrete structures are observed, a registered professional engineer should be contacted to evaluate the stability of the basin.

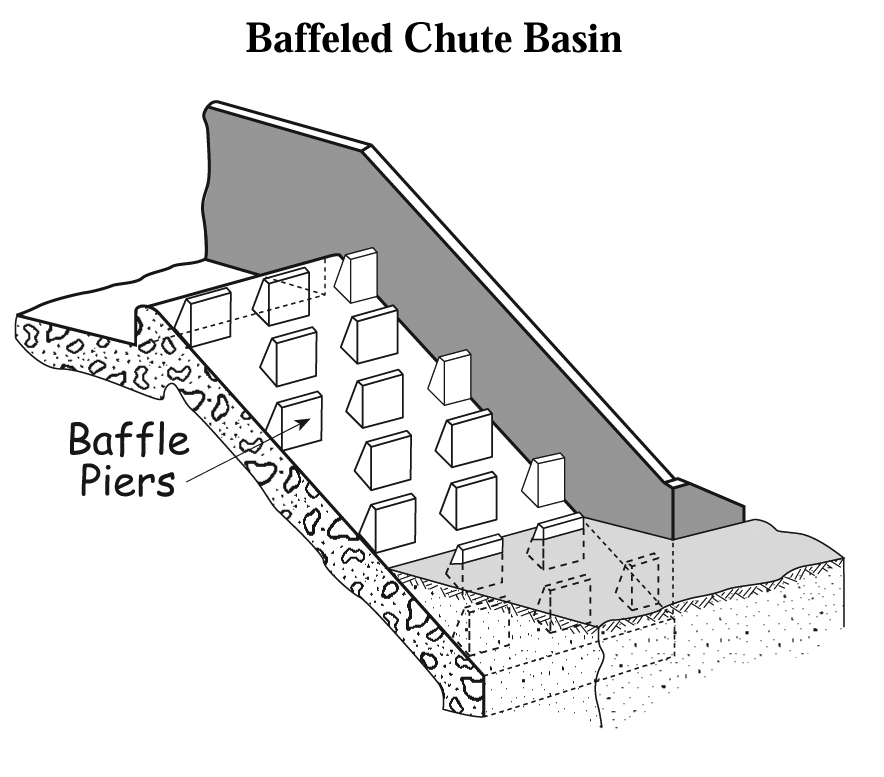

Baffled Chutes

Baffled chutes require no initial tailwater to be effective and are located downstream of the control section. Multiple rows of baffle piers on the chute prevent excessive acceleration of the flow and prevent the damage that occurs from a high discharge velocity. A portion of the baffled chute usually extends below the streambed elevation to prevent undermining of the chute. If any of the severe problems associated with concrete that are referenced in the opening paragraphs are observed, a registered professional engineer should be contacted to evaluate the stability of the outlet.

Baffled chutes require no initial tailwater to be effective and are located downstream of the control section. Multiple rows of baffle piers on the chute prevent excessive acceleration of the flow and prevent the damage that occurs from a high discharge velocity. A portion of the baffled chute usually extends below the streambed elevation to prevent undermining of the chute. If any of the severe problems associated with concrete that are referenced in the opening paragraphs are observed, a registered professional engineer should be contacted to evaluate the stability of the outlet.

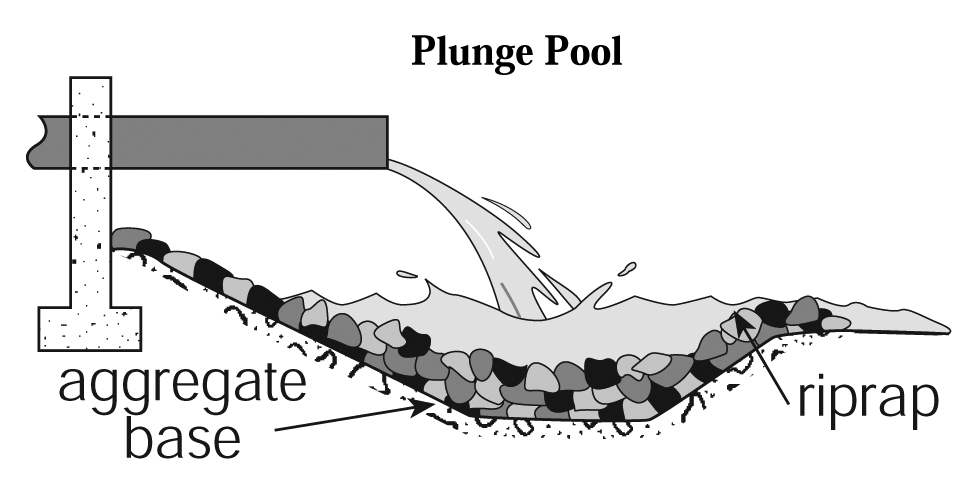

Plunge Pools

A plunge pool is an energy dissipating device located at the outlet of a spillway. Energy is dissipated as the discharge flows into the plunge pool. Plunge pools are commonly lined with rock riprap or other material to prevent excessive erosion of the pool area. Discharge from the plunge pool should be at the natural streambed elevation. Typical problems may include movement of the riprap, loss of fines from the bedding material and scour beyond the riprap and lining. If scour beneath the outlet conduit develops, the conduit will be left unsupported and separation of the conduit joints and undermining may occur. Separation of the conduit joints and undermining may lead to failure of the spillway and ultimately the dam. A registered professional engineer should be contacted to ensure that the plunge pool is designed properly.

A plunge pool is an energy dissipating device located at the outlet of a spillway. Energy is dissipated as the discharge flows into the plunge pool. Plunge pools are commonly lined with rock riprap or other material to prevent excessive erosion of the pool area. Discharge from the plunge pool should be at the natural streambed elevation. Typical problems may include movement of the riprap, loss of fines from the bedding material and scour beyond the riprap and lining. If scour beneath the outlet conduit develops, the conduit will be left unsupported and separation of the conduit joints and undermining may occur. Separation of the conduit joints and undermining may lead to failure of the spillway and ultimately the dam. A registered professional engineer should be contacted to ensure that the plunge pool is designed properly.

Dam Owner Academy: Spillways & Outlet Works

The Dam Owner Academy is a series of videos to educate and inform owners on all aspects of operating and maintaining a dam safely. The videos concisely present the critical basics of owner responsibilities and are available as a free resource for owners and those conducting owner outreach programs.

Outlet erosion control structures are discussed in the "Spillways & Outlet Works" video.